How can you tell if a radiant panel complies with hydronic, plumbing, and building codes?

Floor Microclimat / August 14, 2025

To determine whether a radiant panel complies with hydraulic codes (in this case, Canadian standards or standards specific to Quebec), several criteria must be checked, including design, installation, materials used, and technical specifications. These standards are in place to ensure that the system operates efficiently, safely, and economically. Here are the main steps to determine whether a radiant panel complies with standards:

1. Verification of manufacturer specifications

The manufacturer of the radiant panel should provide a manual or technical specifications detailing the design standards and codes that their product complies with. This includes:

- The materials used (pipes, cables, etc.)

- The thermal load capacity and maximum temperature supported

- The types of fluids (water, glycol) permitted

Ensure that the materials and construction of the panel comply with local requirements. If these specifications are unclear or missing, there may be a risk that the product does not meet standards.

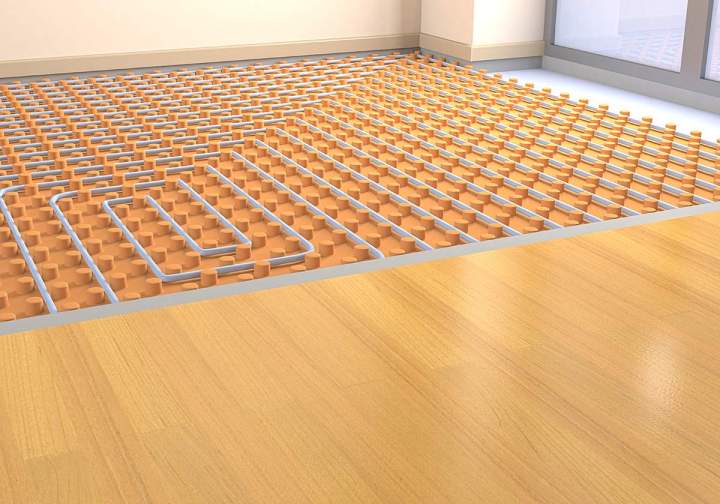

2. Installation in accordance with local standards (building code)

The installation must comply with the building and electrical codes in effect in the region, whether in Canada or Quebec. These rules govern:

- The depth and layout of pipes under the floor

- The minimum distance between heating pipes and other systems such as electrical wiring or insulation

- Frost protection for pipes, if necessary, to prevent the risk of leaks

If the installation does not follow these guidelines, the system may be considered non-compliant.

3. Verification of maximum operating temperature

Another important aspect is the maximum temperature that the system is designed to withstand. A radiant panel operating at a temperature higher than recommended can damage the pipes or cause overheating risks. In most hydraulic systems, the water temperature must not exceed 50-55°C to prevent the pipes from overheating and ensure efficient and safe operation.

4. Type of fluid used

If an antifreeze fluid such as glycol is used, it must comply with environmental and safety standards. Glycol must be mixed in specific proportions to prevent freezing while avoiding overheating of the system. An incorrect mixture or poor-quality fluid can render the system non-compliant.

5. Checking connections and components

All components of the radiant heating system, including pipes, fittings, and valves, must be properly installed and certified to meet safety standards. If non-certified components are used, this could compromise safety and render the system non-compliant with requirements.

6. Inspection by a qualified professional

It is always recommended to have the system installation checked by a qualified professional who can perform an inspection in accordance with local building codes and standards. This professional will be able to check the following:

- The layout of pipes and cables

- The calibration of the system to ensure that it operates at the appropriate temperature and pressure

- The presence of necessary safety valves and pressure regulators

7. Certification and compliance marks

Finally, check that the product has a certification or compliance mark indicating that it meets local standards. For example, in Canada, the product must be certified by organizations such as CSA Group (Canadian Standards Association). If the product does not have this certification, there is a good chance that it does not comply with standards.